ABOUT US

EXACTA STAMPI is a family-run company that has been operating in the field of plastic injection mould construction for various industrial sectors, particularly household goods, since 1967. The company works closely with Exacta Progetti, the enterprise branch in charge of the mould design phase.

Through the years the Company acquired a wide experience and today serves different market sectors like: household plastic goods, gardening products, outdoor furnitures, dustbins for waste separate collection, plastic storage containers from small to very large sizes, thanks to the extreme precision in the creation of the moulds that are accurately manufactured with advanced technology machines and high quality Steel of European origin only. The technical department is equipped with the ultimate CAD/CAM systems in order to offer high performance project service to the customers and create long lasting moulds. On time deliveries is also one of the strength points of the Company, synonym for reliability and seriousness.

Sustainability

European recycled steel and photovoltaic energy. We care for environmental impact!

Exacta Stampi Around The World

We are the trusted partner for both national and international clients, providing innovative solutions and unmatched expertise

Quality

Exacta Stampi, where the excellence and innovation of Made in Italy meet the world.

Since 1967

Since 1967, Exacta Stampi brings decades of experience and advanced know-how in creating high-quality, customized plastic molds

OUR SERVICES

The company offers a comprehensive range of services, from initial consultation to the design and manufacture of the finished mold. Exacta Stampi is able to meet the most specific needs of its customers, thanks to a team of highly qualified professionals and a state-of-the-art machinery park

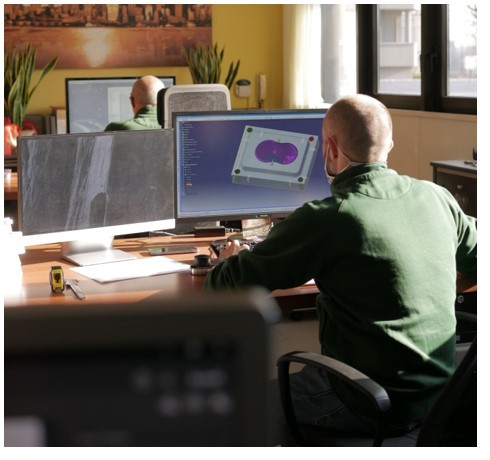

DESIGN

Our highly qualified Technicians, specialized in the design of plastic moulds will closely assist you in the implementation of your project.

CREATION

Thanks to our high performance machineries and skilled technicians, we turn your project into reality.

CUSTOMIZATION

Exacta Stampi can create moulds with any drill type, even deep and complex ones, thanks to the tools designed specifically for the dedicated machinery.

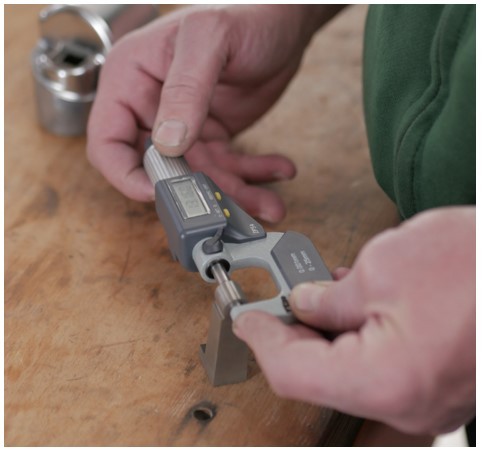

HIGH QUALITY MOULDS

In order to guarantee high quality performance in our products, we regularly execute machine maintenance with extreme accuracy.

The moulds developed within EXACTA STAMPI allow to create plastic products of high aesthetic value whose quality remains unchanged throughout the life cycle of the mould. The Company owes its success not only to its capacity to develop high-quality moulds, which are often highly complex, but also to its ability to foster customer loyalty through understanding customers’ needs and quickly reacting to them.

HIGH QUALITY MOULDS

In order to guarantee high quality performance in our products, we regularly execute machine maintenance with extreme accuracy.

The moulds developed within EXACTA STAMPI allow to create plastic products of high aesthetic value whose quality remains unchanged throughout the life cycle of the mould. The Company owes its success not only to its capacity to develop high-quality moulds, which are often highly complex, but also to its ability to foster customer loyalty through understanding customers’ needs and quickly reacting to them.

A REMARKABLE TECHNOLOGICAL FORCE

Besides having skilled employees, it is essential to avail of the appropriate technology, which is constantly getting updated and becoming more efficient. From this perspective, Exacta Stampi is always on the lookout for the latest and highest-performing engineering solutions, in both design and production.

It should be added that the entire facility is being adapted to the national Industry 4.0 plan, meaning the machines are interconnected so that the company is able to monitor every work in real time and analyse production flows and data.

Deep drilling remains a high added-value mechanical process, especially when linked to the world of moulds. For example, drilling holes of a certain type allows the creation of highly evolved and refined cooling circuits, which means building moulds that are better cooled and, consequently, more productive.

Our values

«In this field, listening and understanding the customer’s needs is crucial and often a flexible and reactive company like ours can represent a real added value»

“We are constantly investing in innovation because we believe that changing production processes can increasingly improve the quality of our work”. In the tooling department we have a range of about 20 machines, including CNC milling and drilling machines, wire-cut and die-sink EDMs as well. We also have two presses for testing and finalizing the moulds”